VT1000 pitting is a smart tool to find little damage, like small holes, on metal surfaces. It helps industries stop big problems before they happen. At IdeaNestle, we love sharing tools that make life easier, and this amazing gadget is a must-know for anyone who cares about keeping their equipment safe. Understanding how VT1000 corrosion works can save time, money, and stress. Let’s explore why this tool is making waves in industries like oil, gas, and food processing!

What Is VT1000 Pitting and Why Does It Matter?

VT1000 pitting is a smart tool used to spot small holes or damage in metals. It is very helpful in keeping machines and equipment safe from big problems. Many industries use it to save money and avoid accidents. When metal gets old or damaged, it can create tiny pits that are hard to see with the naked eye.

This is where VT1000 corrosion comes in handy. It can find these pits quickly and help stop issues before they grow worse. Many industries, like oil and gas, rely on tools like VT1000 corrosion to check for problems early. Without such tools, hidden damage might cause machines to fail, leading to costly repairs. Using VT1000 corrosion also means safety. It ensures equipment works smoothly, protecting workers and saving businesses from big trouble.

How VT1000 Pitting Saves Industries from Big Problems

Industries face big risks when equipment gets damaged. VT1000 corrosion helps by spotting tiny issues before they become disasters. It saves both time and money. This tool works fast, giving companies the power to act quickly. Early detection means industries can fix problems before they shut down operations. Factories and refineries need reliable machines. VT1000 pitting ensures that equipment stays in good condition, preventing breakdowns. By using VT1000 pitting, businesses stay ahead of damage. It is like having a superhero for your machinery, always keeping it safe and strong.

The Secret Power of VT1000 Pitting in Spotting Damage Early

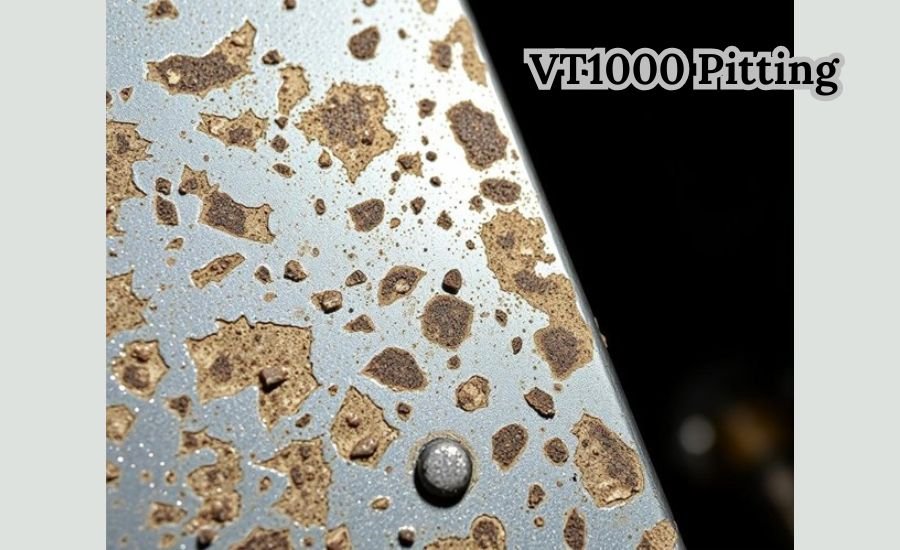

Finding damage early is the best way to avoid costly repairs. VT1000 corrosion uses advanced technology to do just that. It scans metal surfaces and spots tiny flaws. This tool is great for catching what the eye can’t see. Even the smallest pits are detected, helping industries save money. With VT1000 corrosion, you don’t have to worry about missing hidden damage. It works like a detective, ensuring nothing is overlooked. Its precision makes it an excellent choice for companies that care about safety and efficiency. No damage goes unnoticed when VT1000 corrosion is at work.

VT1000 Pitting: A Non-Destructive Hero for Metal Maintenance

Sometimes, checking for damage can harm equipment. But with VT1000 corrosion, there is no need to worry. It is a non-destructive tool. This means it does not damage the surface while looking for pits. It keeps your equipment safe during inspections. Industries love VT1000 corrosion because it helps without causing any harm. It is gentle but very effective. Choosing non-destructive tools like VT1000 pitting is smart. It saves time, money, and the integrity of your machines.

Top 5 Benefits of Using VT1000 Pitting Detection

VT1000 corrosion comes with amazing benefits. First, it finds problems fast, saving industries time. Second, it is very accurate. You can trust it to spot even the smallest damage. Third, it prevents costly repairs. Fixing pits early is cheaper than dealing with major issues later. Fourth, Pitting corrosion in VT1000 keeps workers safe by ensuring equipment runs smoothly. Lastly, it protects your machines, making them last longer and work better.

How to Use VT1000 Pitting for Your Metal Surfaces

Using VT1000 pitting is simple and effective. First, clean the metal surface to remove dirt and grease Next, place the VT1000 tool on the area you want to check. It will scan the surface for damage. Once scanning is complete, review the results. The tool shows where the pits are and how serious they might be. Regular checks with Pitting corrosion in VT1000 can keep your equipment in top condition. It is a small effort for big savings.

VT1000 Pitting Success Stories You Need to Know

Many businesses have benefited from Pitting corrosion in VT1000. In one factory, it found pits that could have caused machine failure. This saved them thousands of dollars. An oil refinery used Pitting corrosion in VT1000 to check their pipes. They found hidden damage and fixed it before any leaks occurred. In another case, a food plant used it to inspect metal surfaces. This helped them maintain safety standards and avoid contamination. These success stories show how Pitting corrosion in VT1000 can make a big difference. It is a tool every industry should have.

Why VT1000 Pitting Is a Game-Changer in Safety Checks

Safety checks are important for industries, and Pitting corrosion in VT1000 makes them better. It ensures no damage is left unseen. By using this tool, companies can avoid accidents. It helps protect workers and keeps operations running smoothly. Pitting corrosion in VT1000 is a game-changer because it works fast and accurately. It gives businesses peace of mind. Having the right tools, like Pitting corrosion in VT1000, means fewer risks and better safety measures.

Common Mistakes to Avoid When Using VT1000 Pitting

Even with great tools, mistakes can happen. One common mistake is not cleaning the surface properly before scanning. Another issue is ignoring small pits found by VT1000 pitting. Small problems can grow into big ones. Always follow the instructions for the tool. Skipping steps can lead to incorrect results. Using Pitting corrosion in VT1000 regularly ensures you stay on top of maintenance and avoid mistakes.

VT1000 Pitting for Beginners: Easy Steps to Get Started

If you’re new to VT1000 pitting, don’t worry. It is easy to learn and use. Start by reading the manual to understand how it works. Knowing the basics helps you use it better. Practice on a clean metal surface. This will show you how the tool detects pits. With some practice, you’ll see how helpful VT1000 surface degradation can be for keeping your equipment safe.

How VT1000 Pitting Helps in Oil, Gas, and Manufacturing

Industries like oil and gas face constant challenges with metal corrosion. VT1000 surface degradation is a lifesaver for them. It helps these industries spot damage early, avoiding leaks and accidents. Manufacturing companies also benefit by keeping machines in top shape. This ensures smooth production. VT1000 surface degradation is trusted across industries because it delivers reliable results every time.

Real-Life Problems Solved with VT1000 Pitting Technology

VT1000 surface degradation has solved many real-life issues. For example, it helped a factory detect pits in a machine part that could have broken during production. In another case, it found corrosion in a refinery’s pipes, preventing costly repairs and downtime. Food industries have used it to ensure their equipment stays safe and clean. This protects their products and customers. Each success shows how VT1000 surface degradation makes a difference in solving problems early.

The Future of VT1000 Pitting: What’s Next?

The technology behind VT1000 surface degradation keeps improving. Future versions may include artificial intelligence for even faster results. Developers are working on making the tool more user-friendly. This will help more people use it with ease. As industries evolve, VT1000 pitting will adapt to meet new challenges. Its future is bright and full of possibilities.

You Need To Know: Adelaide CBD – 0412485090

VT1000 Pitting vs. Traditional Methods: What’s Better?

Traditional methods of finding damage can be slow and less accurate. VT1000 surface degradation, on the other hand, is fast and precise. It saves industries time and money by detecting pits early. This is a big advantage over older methods. VT1000 surface degradation is also non-destructive, making it safer to use on valuable equipment. When compared to traditional tools, VT1000 surface degradation stands out as the smarter choice.

Why VT1000 Pitting Is the Best Tool for Hidden Damage Detection

Hidden damage is hard to find without the right tools. VT1000 pitting solves this problem by detecting even the tiniest pits. Its accuracy and speed make it the best choice for industries. No other tool matches its performance. VT1000 pitting helps businesses save money, improve safety, and extend the life of their equipment. If you care about keeping your machines in great shape, VT1000 pitting is the tool you need.

Conclusion

VT1000 pitting is like a superhero for your machines. It finds small problems before they become big troubles. This tool keeps your equipment safe, helps save money, and stops accidents from happening. Many industries use VT1000 pitting because it works fast and doesn’t harm the metal. It’s the perfect choice for spotting hidden damage and keeping everything running smoothly. If you want to protect your machines and avoid costly repairs, VT1000 pitting is the way to go. It’s simple, smart, and gets the job done. Whether you’re in oil, gas, or manufacturing, this tool will make your work easier and safer. With VT1000 pitting, you can trust that your equipment is always in the best shape!

Must-Have Information: Portable Offices

FAQs

Q: What is VT1000 pitting?

A: VT1000 pitting is a tool that detects small holes or damage on metal surfaces, helping industries find and fix problems early.

Q: How does VT1000 pitting work?

A: It scans metal surfaces using high-resolution imaging to detect tiny pits or flaws that are hard to see with the naked eye.

Q: Why is VT1000 pitting important?

A: It prevents costly repairs and accidents by identifying damage early keeping machines safe and reliable.

Q: Is VT1000 pitting a non-destructive method?

A: Yes, VT1000 pitting does not harm the metal during inspections, making it a safe and effective tool.

Q: What industries use VT1000 pitting?

A: Industries like oil, gas, manufacturing, and food processing use it to maintain safety and equipment quality.

Q: How often should VT1000 pitting be used?

A: It’s best to use it regularly as part of routine maintenance to keep equipment in top condition.

Q: Can beginners use VT1000 pitting?

A: Yes, it is simple to use and comes with instructions that make it easy for anyone to get started.

Q: Does VT1000 pitting save money?

A: Absolutely! By finding damage early, it helps avoid expensive repairs and downtime, saving businesses a lot of money.